cleesgt

New Member

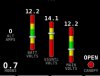

I'm getting 12v readings on a D1000 for Bat & Essential busses (EMS C37 pins 1 & 2), but Main bus (pin 23) reads 4.9 volts. I've spent a couple days trying to figure out why. Facts:

- I took the Volt sensor definition file and added pin 23 to accept a voltage readout: C37_P1 C37_P2 C37_P23

- checked DB 37 connector pin 23 where it connects to EMS and it reads ~12v.

- checked Sensor Debug Data - Value column reads 4.99xx, Raw column reads 4093 (constant).

- checked Sensor Input Mapping wizard and copied Bat settings to Main (identical, but one reads accurately, the other doesn't).

Floundering and need some advice. Thanks

- I took the Volt sensor definition file and added pin 23 to accept a voltage readout: C37_P1 C37_P2 C37_P23

- checked DB 37 connector pin 23 where it connects to EMS and it reads ~12v.

- checked Sensor Debug Data - Value column reads 4.99xx, Raw column reads 4093 (constant).

- checked Sensor Input Mapping wizard and copied Bat settings to Main (identical, but one reads accurately, the other doesn't).

Floundering and need some advice. Thanks