donramm

New Member

I took my RV-12 in for transponder and pitot-static bi-annual check. I only fly VFR. The tech administering the test asked me if I wanted to do an IFR check of the pitot-static system. Not know what that implied I said "Sure". He covered one static port, put a tube on pitot tube, and put a gizmo over the other static port and turned a pump on. He "raised" the altitude to 2000' MSL and hit the button to stop the pump (which is actually sucking vs. blowing, of course). On an IFR check the altitude is supposed to change at no more than 100 feet/minute (or something like that). Mine went very abruptly to field elevation. So, my static system apparently has a leak. I told tech I would check the system and return to retest.

I have looked for leaks in what is very simple plumbing for the static system in an RV-12 and found none. I heard Paul New, one of the hosts of the "Ask the A&Ps" podcast, suggest using a plastic syringe to do some testing on my own. I covered one static port, insert the tip of the plastic syringe I purchased in the other static port (ensuring I have an air-tight fit) and I get same results as when the tech did test with $$$ equipment. I "raise" the altitude up to 2000' by **slowly** pulling the plunger out on the syringe and when I stop, the altitude quickly returns to field elevation.

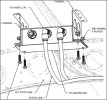

I disconnected the static system tube from the ADAHRS and hooked up a very low pressure air source, plugged both static ports, and checked for leaks in the 5 junction points in the static system (inside of static ports and the "T" that joins the tubes from the static ports and connects them to the ADAHRS) and found none.

I did this testing in "Test Mode" and not in "Test Mode" of ADAHRS and get same result.

How can I check the ADAHRS unit itself?

It is probably obvious: I did not build my RV-12.

I have looked for leaks in what is very simple plumbing for the static system in an RV-12 and found none. I heard Paul New, one of the hosts of the "Ask the A&Ps" podcast, suggest using a plastic syringe to do some testing on my own. I covered one static port, insert the tip of the plastic syringe I purchased in the other static port (ensuring I have an air-tight fit) and I get same results as when the tech did test with $$$ equipment. I "raise" the altitude up to 2000' by **slowly** pulling the plunger out on the syringe and when I stop, the altitude quickly returns to field elevation.

I disconnected the static system tube from the ADAHRS and hooked up a very low pressure air source, plugged both static ports, and checked for leaks in the 5 junction points in the static system (inside of static ports and the "T" that joins the tubes from the static ports and connects them to the ADAHRS) and found none.

I did this testing in "Test Mode" and not in "Test Mode" of ADAHRS and get same result.

How can I check the ADAHRS unit itself?

It is probably obvious: I did not build my RV-12.

Last edited: