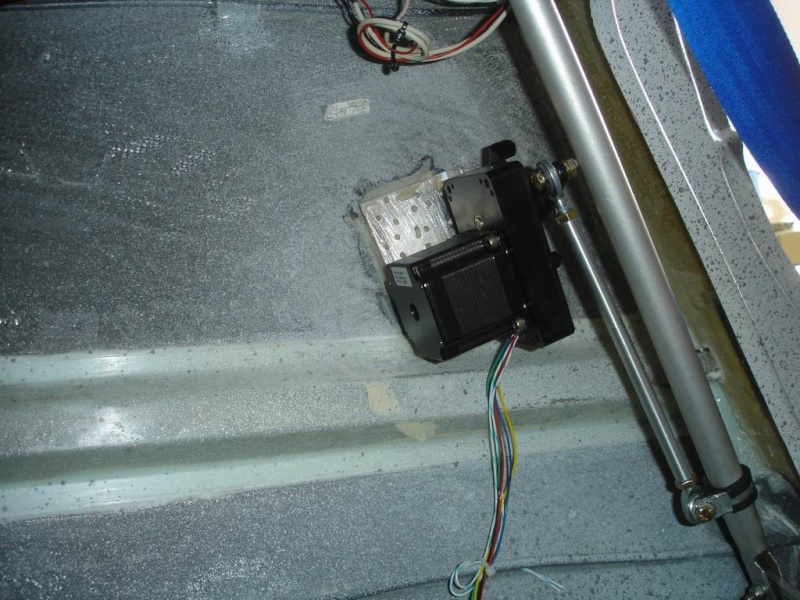

Before I signed up a few days ago I viewed a servo installation photo of what I believe was in a Sonex on this site. First I must say, I know nothing about autopilots other that I'm starting to install one in my RV-10 (under construction) . I do know a little about adel clamps.

In this photo the owner attached the non-servo rod end to an adel clamp that was clamped arround a control tube for the aircraft. I could not comment while viewing as I did not have my pass working and was not logged in. I'm concerned that if this adel clamp would slip (as they do some times) it may create a jambed control . If someone can locate this photo and shed some light on my concern I would appreciate it.

Thanks Ron

In this photo the owner attached the non-servo rod end to an adel clamp that was clamped arround a control tube for the aircraft. I could not comment while viewing as I did not have my pass working and was not logged in. I'm concerned that if this adel clamp would slip (as they do some times) it may create a jambed control . If someone can locate this photo and shed some light on my concern I would appreciate it.

Thanks Ron