You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

D3 fit to panel with 2-1/4" (57mm dia.) hole, not 80mm ?

- Thread starter Lancaster

- Start date

Rhino

Well-Known Member

- Joined

- Jul 20, 2009

- Messages

- 1,737

Is it possible? Yes. Has anyone done it? I have no clue. The cradle the D3 mounts to has two relatively large holes in it. That's where you would stick your fingers in to pinch when using the pinch mount. Without the pinch mechanism attached, there's just two holes in the cradle. I've never see a specific measurement for them, but they appear to be about an inch apart (see picture in the link below). So, there should be no reason you couldn't fabricate a simple spring clamp or similar such attachment to make it fit a 2 1/4" hole. I'm not even going to attempt to address whether or not that constitutes 'permanent' installation if it's a certified aircraft (not my area of expertise). You can even order a spare cradle from Dynon if you don't want to use one that came with the D3.

Thank you, Rhino. Yes, I had bought the cradle and had watched the videos showing the detail of the pinch mount. Trying to figure out excatly how to do it before I get the actual hardware has got the better of me so far, though. Fortunately, my a/c is Permit (LAA, UK) so non-certified.

Rhino

Well-Known Member

- Joined

- Jul 20, 2009

- Messages

- 1,737

I would make a blank plate for the existing instrument hole, drill holes in it that to match the existing hole pattern in the D3 cradle, and attach the D3 cradle to that.

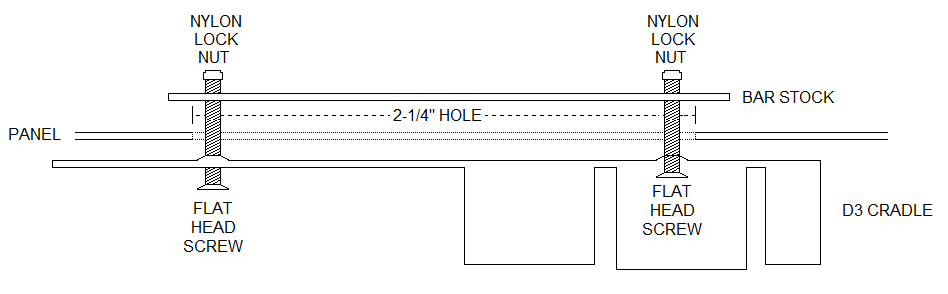

Alternatively, I would fabricate a clamping bar that's slightly larger than the 2 1/4" hole, maybe a piece of 1/2" or 3/4" wide, flat aluminum bar stock. Drill a hole in each end of the bar stock near the edge of the 2 1/4" panel hole diameter. I don't have a cradle to measure, but if the diameter of the recessed (dimpled) holes for flat head screws are close enough to fit in the 2 1/4" hole, I'd use those to put a couple of screws through the cradle and the bar stock, with nylon lock nuts on the back. Feel free to laugh at the artwork. I don't have the tools to make a proper diagram, and it's been many, many years since my engineering drawing classes in college. And the screws would obviously be shorter than depicted here.

If the existing recessed holes in the cradle are farther apart than your 57mm panel hole, you might need to get a bit more creative. You could drill new holes in the cradle, but you may have to recess them to allow the D3 to fit flush in the cradle (I don't know how much room there is).

These are just first thoughts. I might come up with something different given more time, and I'm sure others here will have their own ideas that might be better.

And if all else fails, there's always velcro. ;-)

Alternatively, I would fabricate a clamping bar that's slightly larger than the 2 1/4" hole, maybe a piece of 1/2" or 3/4" wide, flat aluminum bar stock. Drill a hole in each end of the bar stock near the edge of the 2 1/4" panel hole diameter. I don't have a cradle to measure, but if the diameter of the recessed (dimpled) holes for flat head screws are close enough to fit in the 2 1/4" hole, I'd use those to put a couple of screws through the cradle and the bar stock, with nylon lock nuts on the back. Feel free to laugh at the artwork. I don't have the tools to make a proper diagram, and it's been many, many years since my engineering drawing classes in college. And the screws would obviously be shorter than depicted here.

If the existing recessed holes in the cradle are farther apart than your 57mm panel hole, you might need to get a bit more creative. You could drill new holes in the cradle, but you may have to recess them to allow the D3 to fit flush in the cradle (I don't know how much room there is).

These are just first thoughts. I might come up with something different given more time, and I'm sure others here will have their own ideas that might be better.

And if all else fails, there's always velcro. ;-)

Last edited:

Excellent suggestions, Rhino. I really appreciate this. I am going to tempoarily Velcro the cradle first and check the best position, then try your ideas. Access to the back of the panel at this area is quite difficult, so am thinking your first approach has a lot of merit. ( I think my mechanical CAD capabilities have also atrophied in my retirement, too !). Thanks again.