You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Always shows a headwind

- Thread starter cwood2000

- Start date

- Joined

- Jul 19, 2010

- Messages

- 276

As others have already said, this is an indicated airspeed problem and is likely due to a static system error. If the Dynon is getting the wrong indicated airspeed, the TAS calculation is wrong and causes it to always show a headwind or tailwind depending on the direction of the IAS error.

Just an update. The switch was indeed upside down, so correcting that improved the performance, but not 100%. I did a static check with a test rig an A&P has that I know and still shown a leak down. I used the push to connect fittings from Cleveland and under pressure could make them leak so I replaced them with compression fittings. I repeated the leak test and it is hold steady. I'll re test in flight as soon as weather allows.

Next time you fly do both a "high speed" and "slow speed" test then let us know the results. You are heading in the right direction to make this right. There are too many variables involved so you might not get it "100% perfect" under every condition but as long as you get it to be less than 3Kts under every condition then it is more than good enough for a modern EFIS system.

Last edited:

DBRV10

Active Member

Just an update. The switch was indeed upside down, so correcting that improved the performance, but not 100%. I did a static check with a test rig an A&P has that I know and still shown a leak down. I used the push to connect fittings from Cleveland and under pressure could make them leak so I replaced them with compression fittings. I repeated the leak test and it is hold steady. I'll re test in flight as soon as weather allows.

And these push fitting, which Dynon supply too.......are the cause of all the leaks I find in the field. they are designed to operate under 90 PSI from an air compressor like in a factory or your home workshop.

The best solution is simply buy the Dynon Static port and tube kit but throw away the push on fittings and use the Nylo seal fittings from Aircraft Spruce. The Dynon Static Port is in my experience the best for RV model aircraft with the most accurate results.

From my exposure to these issues 100% of the RV's with the Dynon port have been really accurate, every other port has not, and by a large margin. I found another RV10 last week with 260' errors from the static port. I could have blamed the G3x but....it was the port.

I’ve been following this thread and was not surprised to see a leak was the cause. I had a new Dynon system installed in my airplane and when I picked it up my IAS at cruise power was 10 knots low and the winds were unreliable. After months and months of reading and flying I finally put a piece of 0.032 safety wire in front of the static ports. IAS now read properly and the winds were fine. I spent some time making up a shim to bond onto the static port but pretty soon two years were up and it was time for the pitot static check. We found a pitot leak behind the panel. I fixed it, took the safety wire off in front of the static ports and voila - Everything was fine. A pitot static check had not been done after new panel installation yet it was signed off.

The pneumatic fittings and poly tubing come from SafeAir, also sold by Cleaveland Tool Co. The only thing needed for leak-free connections is a square, clean cut of the tubing with an appropriate tubing cutter. I have the system on my RV-10, and have zero trouble passing a leak test after disconnect and reconnect a fitting. No problem with static test, no problem with speeds or wind calcs.And these push fitting, which Dynon supply too.......are the cause of all the leaks I find in the field. they are designed to operate under 90 PSI from an air compressor like in a factory or your home workshop.

The best solution is simply buy the Dynon Static port and tube kit but throw away the push on fittings and use the Nylo seal fittings from Aircraft Spruce. The Dynon Static Port is in my experience the best for RV model aircraft with the most accurate results.

From my exposure to these issues 100% of the RV's with the Dynon port have been really accurate, every other port has not, and by a large margin. I found another RV10 last week with 260' errors from the static port. I could have blamed the G3x but....it was the port.

If you have leak problems you aren't making clean cuts or you aren't fully seating the tubing in the connection. I've never had static system so easy to make leak free. Nylo fittings are more prone to leaks, over-tightening, under-tightening.

DBRV10

Active Member

Kelly, I agree 100% about clean cuts using the correct tools. But how many aircraft is your sample of experience? Mine is quite a lot. I have zero Nylo fitting problems.......yes zero. I have in frustration with proper cutting etc.....and understand my industrial automation days used lots of these fittings had plenty of incurable leaks. I will grant you some times they work OK. Trust me they are easy to work with and I am lazy, but rework is my enemy.

This is not my first rodeo, and over time, some things work better. YMMV.

This is not my first rodeo, and over time, some things work better. YMMV.

This is a very important piece if information I forgot to mention. Unless you are very skilled (or lucky) using wire cutters, scissors or even box cutters to cut the tube almost always results in a leaky fitting. I have this inexpensive plastic tube cutting tool and it works great.The pneumatic fittings and poly tubing come from SafeAir, also sold by Cleaveland Tool Co. The only thing needed for leak-free connections is a square, clean cut of the tubing with an appropriate tubing cutter. I have the system on my RV-10, and have zero trouble passing a leak test after disconnect and reconnect a fitting. No problem with static test, no problem with speeds or wind calcs.

If you have leak problems you aren't making clean cuts or you aren't fully seating the tubing in the connection. I've never had static system so easy to make leak free. Nylo fittings are more prone to leaks, over-tightening, under-tightening.

----------------------------------------

DBRV10 are these the ones from ACS you use?

Last edited:

I agree that various systems can work better than others. I do tech counselor visits on a number of experimental aircraft, few have problems with the SafeAir tubing and fittings. As an A&P/IA I have experience with a number of older vacuum and static systems connected to old six-pack systems...generally a mixed bag, requiring a lot of care to get leak-free.Kelly, I agree 100% about clean cuts using the correct tools. But how many aircraft is your sample of experience? Mine is quite a lot. I have zero Nylo fitting problems.......yes zero. I have in frustration with proper cutting etc.....and understand my industrial automation days used lots of these fittings had plenty of incurable leaks. I will grant you some times they work OK. Trust me they are easy to work with and I am lazy, but rework is my enemy.

This is not my first rodeo, and over time, some things work better. YMMV.

Kelly

Now "The rest of the story". I replaced all the push to connect fittings with very robust compression fittings from the dental industry, they are brass and consist of a barb, plastic crush ring and brass nut. Using a hand pump I could not get a vacuum and the system would not hold pressure, I did a bubble test under pressure from the hand pump for each fitting and found no leaks. It was driving me nuts, so I started to isolate each part of the system. I disconnected the ports and they checked find with a vacuum, so that was one small victory. I plugged off the ADAHRS and Alt Switch and put a air valve in the line and pumped 50psi with my compressor and could not get it to hold any pressure, obviously a big leak. I was in the back of the plane and a guy helping said he heard a hiss that seemed to be near the left wing root. So we changed places and I got a stethoscope and sure enough could hear a significant leak, so I took off the wing root fairing. I had used a push to connect union (and forgot about it) and sure enough it was leaking. Once replaced and everything connected we held vacuum at 1,000' for an hour or so and did a dance. Today I did a flight test and all is good. My TAS is where it should be and now showing the appropriate tail winds. Thank to all of you for walking through my self made mine field and totally agree the push connects, no matter how good, are not good enough. I sure learned a lesson about checking the system out as it is installed, rather than hoping it works in flight, a very valuable lesson.

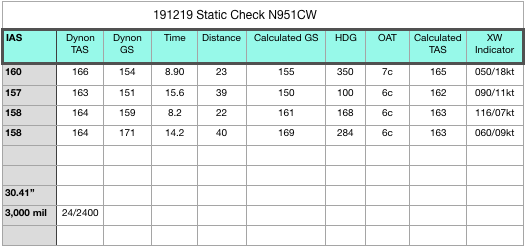

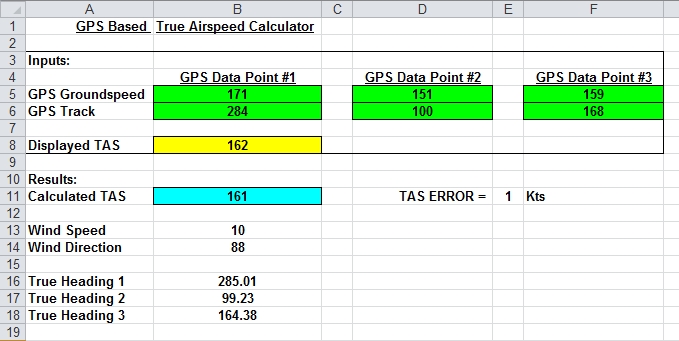

AWESOME!!!! With the numbers you just posted your GPS based independent TAS is within 1Kt of the SkyView displayed TAS. Well within the 3Kt acceptable range and probably just due to rounding up/down the numbers used in the calculations.

Last edited:

DBRV10

Active Member

Yay.....

Never trust anything

Never trust anything